A | B | C | D | E | F | G | H | CH | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns.[1][2][3][4][5][6][7]

Textiles are divided into two groups: Domestic purposes and technical textiles. In consumer textiles, aesthetics and comfort are the most important factors, but in technical textiles, functional properties are the priority.[7][8]

Geotextiles, industrial textiles, medical textiles, and many other areas are examples of technical textiles, whereas clothing and furnishings are examples of consumer textiles. Each component of a textile product, including fiber, yarn, fabric, processing, and finishing, affects the final product. Components may vary among various textile products as they are selected based on their fitness for purpose.[7][9][8]

Fiber is the smallest component of a fabric; fibers are typically spun into yarn, and yarns are used to manufacture fabrics.[10][9] Fiber has a hair-like appearance and a higher length-to-width ratio. The sources of fibers may be natural, synthetic, or both. The techniques of felting and bonding directly transform fibers into fabric. In other cases, yarns are manipulated with different fabric manufacturing systems to produce various fabric constructions. The fibers are twisted or laid out to make a long, continuous strand of yarn.[2] Yarns are then used to make different kinds of fabric by weaving, knitting, crocheting, knotting, tatting, or braiding.[11][12][6] After manufacturing, textile materials are processed and finished to add value, such as aesthetics, physical characteristics, and increased usefulness.[13] The manufacturing of textiles is the oldest industrial art.[14] Dyeing, printing, and embroidery are all different decorative arts applied to textile materials.[15]

Etymology

Textile

The word 'textile' comes from the Latin adjective textilis, meaning 'woven', which itself stems from textus, the past participle of the verb texere, 'to weave'.[5] Originally applied to woven fabrics, the term "textiles" is now used to encompass a diverse range of materials, including fibers, yarns, and fabrics, as well as other related items.[2][1][3]

Fabric

A "fabric" is defined as any thin, flexible material made from yarn, directly from fibers, polymeric film, foam, or any combination of these techniques. Fabric has a broader application than cloth.[16]: 207 [17] Fabric is synonymous with cloth, material, goods, or piece goods.[7][6] The word 'fabric' also derives from Latin, with roots in the Proto-Indo-European language. Stemming most recently from the Middle French fabrique, or "building," and earlier from the Latin fabrica ('workshop; an art, trade; a skillful production, structure, fabric'), the noun fabrica stems from the Latin faber" artisan who works in hard materials', which itself is derived from the Proto-Indo-European dhabh-, meaning 'to fit together'.[18]

Cloth

Cloth is a kind of fabric that consists of a fine, flexible network of yarns. While the term "cloth" is synonymous with fabric, not all fabrics can be defined as cloth.[16]: 207 [clarification needed] The word 'cloth' derives from the Old English clað, meaning "a cloth, woven, or felted material to wrap around one's body', from the Proto-Germanic kalithaz, similar to the Old Frisian klath, the Middle Dutch cleet, the Middle High German kleit and the German kleid, all meaning 'garment'.[19]

History

Textiles themselves are too fragile to survive across millennia; the tools used for spinning and weaving make up most prehistoric evidence for textile work. The earliest tool for spinning was the spindle to which a whorl was eventually added. The weight of the whorl improved the thickness and twist of spun thread. Later the spinning wheel was invented. Historians are unsure where; some say China and others India.[20]

The precursor of today's textiles includes leaves, barks, fur pelts, and felted cloths.[21]

The Banton Burial Cloth, the oldest existing example of warp ikat in Southeast Asia, is displayed at the National Museum of the Philippines. The cloth was most likely made by the native Asian people of the northwest Romblon. The first clothes, worn at least 70,000 years ago and perhaps much earlier, were probably made of animal skins and helped protect early humans from the elements. At some point, people learned to weave plant fibers into textiles. The discovery of dyed flax fibers in a cave in the Republic of Georgia dated to 34,000 BCE suggests that textile-like materials were made as early as the Paleolithic era.[22][23]

The speed and scale of textile production have been altered almost beyond recognition by industrialization and the introduction of modern manufacturing techniques.[24]

Textile industry

The textile industry grew out of art and craft and was kept going by guilds. In the 18th and 19th centuries, during the industrial revolution, it became increasingly mechanized. In 1765, when a machine for spinning wool or cotton called the spinning jenny was invented in the United Kingdom, textile production became the first economic activity to be industrialised. In the 20th century, science and technology were driving forces.[25][26]

Naming

Most textiles were called by their generic names, their place of origin, or were put into groups based loosely on manufacturing techniques, characteristics, and on their designs.[27][28][29][30] Nylon, Olefin, Acrylic are all generic names for some synthetic fibers.[7]: 219

| Name | Product | Textiles named by | Description | |

|---|---|---|---|---|

| Cashmere | Wool fiber obtained from cashmere goats | Origin | Kashmir | Cashmere is synonymous with the Kashmir shawl, with the term "cashmere" derived from an anglicisation of Kashmir.[31] |

| Calico | Plain weave textile material | Origin | Calicut | The fabric originated in the southwestern Indian city of Calicut. |

| Jaconet | Lightweight cotton fabric in plain weave | Origin | Jagannath Puri | Jaconet is anglicisation of Jagannath where it was originally produced.[32] |

| Jersey | A type of Knitted fabric | Origin | Jersey, Channel Islands | Jersey fabric was produced first at Jersey, Channel Islands.[31] |

| Kersey | A coarse woolen cloth | Origin | Kersey, Suffolk | The fabric is named after the town in the east of England.[31] |

| Paisley (design) | A type of motif | Design | Paisley, Renfrewshire | A town situated in the west central Lowlands of Scotland.[31] |

| Dosuti | A handspun cotton cloth | Characteristics | A coarse and thick cotton cloth | In and around the 19th century Punjab and Gujarat were famous destination for various handspun cloths. Dosuti was distinguished by the number of yarns used to produce it. Eksuti was another variation with a single thread. |

| Mulmul types such as āb-i-ravān running water, Baft Hawa woven air[35] | Fine muslin fabric variations from Dacca in Bengal | Characteristics | Delicate muslin types | Dacca, India's eastern subcontinent, had a wide range of handwoven and spun muslins. Baft Hawa, which means "woven air", Shabnam, which means "evening dew", and ab-i-ravan, which means "flowing water" are some poetic names for soft muslins.[35][36] |

| Nainsook | A plain weave fabric with soft hand | Characteristics | Pleasing to the eyes | Nain + Sook translates to "eye-pleasing".[32] |

| Swanskin | A woven flannel cloth | Characteristics | Appears and feels like swan skin | A18th century fabric developed at Shaftesbury.[37] |

| Tansukh | Another type of Muslin with soft and delicate texture | Characteristics | Pleasing to the body | Tan + Sukh translates to "body pleasing". Tansukh was a fine, soft, and delicate textured cloth. The cloth type is mentioned in the 16th century Mughal time records, Ain-i-Akbari.[38] |

Related terms

The related words "fabric"[12] and "cloth"[4] and "material" are often used in textile assembly trades (such as tailoring and dressmaking) as synonyms for textile. However, there are subtle differences in these terms in specialized usage. A textile is any material made of interlacing fibers, including carpeting and geotextiles, which may not necessarily be used in the production of further goods, such as clothing and upholstery. A fabric is a material made through weaving, knitting, spreading, felting, stitching, crocheting or bonding that may be used in the production of further products, such as clothing and upholstery, thus requiring a further step of the production. Cloth may also be used synonymously with fabric, but often specifically refers to a piece of fabric that has been processed or cut.[citation needed]

- Greige goods: Textiles that are raw and unfinished are referred to as greige goods. After manufacturing, the materials are processed and finished.[39][13]

- Piece goods: Piece goods were textile materials sold in cut pieces as specified by the buyer. Piece goods were either cut from a fabric roll or made to a specific length, also known as yard goods.[40][41]

Types

Textiles are various materials made from fibers and yarns. The term "textile" was originally only used to refer to woven fabrics, but today it covers a broad range of subjects.[1] Textiles are classified at various levels, such as according to fiber origin (natural or synthetic), structure (woven, knitted, nonwoven), finish, etc.[27][28][29][30] However, there are primarily two types of textiles:

Consumer textiles

Textiles have an assortment of uses, the most common of which are for clothing and for containers such as bags and baskets. In the household, textiles are used in carpeting, upholstered furnishings, window shades, towels, coverings for tables, beds, and other flat surfaces, and in art. Textiles are used in many traditional hand crafts such as sewing, quilting, and embroidery.[7]

Technical textiles

Textiles produced for industrial purposes, and designed and chosen for technical characteristics beyond their appearance, are commonly referred to as technical textiles. Technical textiles include textile structures for automotive applications, medical textiles (such as implants), geotextile (reinforcement of embankments), agrotextiles (textiles for crop protection), protective clothing (such as clothing resistant to heat and radiation for fire fighter clothing, against molten metals for welders, stab protection, and bullet proof vests).

In the workplace, textiles can be used in industrial and scientific processes such as filtering. Miscellaneous uses include flags, backpacks, tents, nets, cleaning rags, transportation devices such as balloons, kites, sails, and parachutes; textiles are also used to provide strengthening in composite materials such as fibreglass and industrial geotextiles.[7][8]

Due to the often highly technical and legal requirements of these products, these textiles are typically tested in order to ensure they meet stringent performance requirements. Other forms of technical textiles may be produced to experiment with their scientific qualities and to explore the possible benefits they may have in the future. Threads coated with zinc oxide nanowires, when woven into fabric, have been shown capable of "self-powering nanosystems", using vibrations created by everyday actions like wind or body movements to generate energy.[42][43]

Significance

Textiles are all around us. The textile is a component of basic needs like food and shelter. Textiles are everywhere in our lives, from bath towels to space suits. Textiles help humans by comforting, protecting, and extending their lives. Textiles meet our clothing needs, keeping us warm in the winter and cool in the summer. There are several applications for textiles, such as medical textiles, intelligent textiles, and automotive textiles. All of them contribute to the well-being of humans.[2]

Serviceability in textiles

The term "serviceability" refers to a textile product's ability to meet the needs of consumers. The emphasis is on knowing the target market and matching the needs of the target market to the product's serviceability. Serviceability in textiles or Performance is the ability of textile materials to withstand various conditions, environments, and hazards. Aesthetics, durability, comfort and safety, appearance retention, care, environmental impact, and cost are the serviceability concepts employed in structuring the material.[2]: 1 to 12

Components

Fibers, yarns, fabric construction, and finishes and designing are the various components of a textile product. The selection of components varies with the intended use. Henceforth, the fibers, yarns, and fabric manufacturing systems are selected with consideration of the required performance.[2]: 1 to 12

Use and applications

| Commercial textiles/ Domestic textiles | End uses | Technical textiles/ Industrial purpose textiles | End uses |

|---|---|---|---|

| Clothing | Clothing items for men, women and children. nightwear, sportswear, lingerie, undergarments, swimsuit. Accessories such as caps, umbrella, socks, gloves, and handbags.[7][44] | Agro-textiles | Agro-textiles are used in agriculture, horticulture, aquaculture, landscape gardening and forestry. Mainly for crop protection, in crop development for instance shade nets, thermal insulation and sunscreen materials, windshield, antibird nets, covering livestock protection, suppressing weed and insect control, etc.[45] |

| Furnishing | Upholstery, curtains, draperies, carpets, towels.[7][44] | Geotextile | Technical textiles which are used in civil engineering, roads, airfields, railroads, embankments, retaining structures, reservoirs, canals, dams, bank protection, coastal engineering and construction site silt fences, and protection of melting glaciers.[46] |

| Bedding | Bed sheets, khes, blankets, pillows.[7][44] | Automotive textile | Airbags, seat belts, headliners, upholstery, car carpets, and door card.[47] |

| Others | Shower curtains.[7] | Medical textile | implants, sutures, dressings, bandages, medical gowns, face masks.[7] |

| Indutech | This particular sector includes conveyor belts, drive belts, ropes and cordages, filtration products, glass battery separators, decatising and bolting cloth, AGM (absorption glass mat) plasma screens, coated abrasives, composite materials, printed circuit boards, printer ribbon, seals, gaskets, paper making fabrics.[8] |

Other uses

Textiles, textile production, and clothing were necessities of life in prehistory, intertwined with the social, economic, and religious systems. Other than clothing, textile crafts produced utilitarian, symbolic, and opulent items. Archaeological artifacts from the Stone Age and the Iron Age in Central Europe are used to examine prehistoric clothing and its role in forming individual and group identities.[48]

Source of knowledge

Artifacts unearthed in various archaeological excavations informs us about the remains of past human life and their activities.[49] Dyed flax fibers discovered in the Republic of Georgia indicate that textile-like materials were developed during the Paleolithic period. Radiocarbon dates the microscopic fibers to 36,000 years ago, when modern humans migrated from Africa.[23]

Several textile remnants, such as the Inca Empire's textile arts remnants, which embody the Incas' aesthetics and social ideals, serve as a means for disseminating information about numerous civilizations, customs, and cultures.[50][51]

There are textile museums that display history related to many aspects of textiles. The Textile Museum raises public awareness and appreciation of the artistic merits and cultural significance of the world's textiles on a local, national, and international scale. Textile Museum in Washington, D.C., was established in 1925.[52]

Narrative art

The Bayeux Tapestry is a rare example of secular Romanesque art. The art work depicts the Norman Conquest of England in 1066.[53][54]

Decorative art

Textiles are also used for decorative art. Appliqué work of pipili is decorative art of Odisha, a state in eastern India, used for umbrellas, wall hangings, lamp sheds, and bags. To make a range of decorative products, colored clothes are sewn in the shapes of animals, birds, flowers, and magnificent walls on a base cloth.[55]

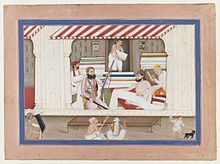

Architextiles

Architextiles, a combination of the words architecture and textile, are textile-based assemblages. Awnings are a basic type of architectural textile.[56] Mughal Shahi Lal Dera Tent, which was a movable palace, is an example of the architextiles of the Mughal period.[57]

Currency

Textiles had been used as currency as well. In Africa, textiles were used as currency in addition to being used for clothing, headwear, swaddling, tents, sails, bags, sacks, carpets, rugs, curtains, etc.[58]Along the east–west axis in sub-Saharan Africa, cloth strip, which was typically produced in the savannah, was used as a form of currency.[59]

Votive offeringedit

Textiles were among the objects offered to the gods votive offering in ancient Greece for religious purposes.[60]

Fiberedit

The smallest component of a fabric is fiber; fibers are typically spun into yarn, and yarns are used to make fabrics. Fibers are very thin and hair-like structures. The sources of fibers may be natural, synthetic, or both.[2][16]: 64, 69

Global consumptionedit

Global fiber production per person has increased from 8.4 kilograms in 1975 to 14.3 kilograms in 2021. After a modest drop due to COVID-19 pandemic in 2020, global fiber output rebounded to 113 million tons in 2021. Global fiber output roughly doubled from 58 million tons in 2000 to 113 million tons in 2021 and is anticipated to reach 149 million tons in 2030.[61]

The demand for synthetic fibers is increasing rapidly. This has numerous causes. Reasons include its low price, the demand-supply imbalance of cotton, and its Synthetic fibers' versatility in design and application. Synthetic fibers accounts for 70% of global fiber use, mainly polyester.[62] By 2030, the synthetic fiber market will reach 98.21 billion US dollars. From 2022 to 2030, the market is anticipated to increase by 5.1% per year.[63]

Fiber Sourcesedit

- Natural fibers are obtained from plants, animals and minerals.[2]: 18 Since prehistoric times, textiles have been made from natural fibers. Natural fibers are further categorized as cellulosic, protein, and mineral.[16]: 70

- Synthetic or manmade fibers are manufactured with chemical synthesis.[2]: 18

- Semi-synthetic: A subset of synthetic or manmade fibers is semi-synthetic fiber. Rayon is a classified as a semi-synthetic fiber, made with natural polymers.

Monomers are the building blocks of polymers. Polymers in fibers are of two types: additive or condensation. Natural fibers, such as cotton and wool, have a condensation polymer type, whereas synthetic fibers can have either an additive or a condensation polymer type. For example, acrylic fiber and olefin fibers have additive polymers, and nylon and polyester are condensation polymers.[16]

Typesedit

| Natural | Synthetic | Semi-synthetic | ||

|---|---|---|---|---|

| Cellulosic fibers (Vegetable or plant fibers) | Protein fibers (Animal fibers) | Mineral fibers | Petroleum based | Cellulose based |

| Cotton | Wool | Asbestos | Nylon | Rayon |

| Linen | Silk | Glass fiber | Polyester

Zdroj:https://en.wikipedia.org?pojem=Textiles >Text je dostupný pod licencí Creative Commons Uveďte autora – Zachovejte licenci, případně za dalších podmínek. Podrobnosti naleznete na stránce Podmínky užití. Zdroj: Wikipedia.org - čítajte viac o Textiles

Text je dostupný za podmienok Creative

Commons Attribution/Share-Alike License 3.0 Unported; prípadne za ďalších

podmienok. | |